The world is becoming more dangerous, with criminals and other hostile players using ground transportation systems to covertly move illegal goods and weapons. Fortunately, advanced X-ray scanning solutions built by Leidos and LINEV Systems are making it much easier for customs and security officials to see inside ground vehicles and shipping containers, so that these threats can be rooted out before they reach their final destinations.

To get a better idea how this screening technology is being improved and deployed, TSI magazine spoke to Leidos’ SVP/business area leader Michael Van Gelder and LINEV Systems’ UK managing director Rob Keeler to find out.

So, who are Leidos and LINEV Systems?

“For 30 years, Leidos has been a global leader of advanced security screening solutions to help safeguard the flow of regulated commerce through the secure, efficient movement of all trade elements, including cargo, vehicles, and people, through ports and borders worldwide,” replied Van Gelder. “Our solutions leverage innovations in screening technologies, common interface, and AI/ML to effectively detect and mitigate threats.”

Meanwhile, LINEV Systems is a global company offering AI-driven X-ray security solutions, with operations across the United States, United Kingdom, EU and UAE. “Our expertise is centered around cutting-edge solutions for full-vehicle and cargo X-ray scanners, relocatable systems, and multi-lane security screening,” Keeler said. “Our AI-enhanced vehicle scanners leverage never-seen-before multi-energy imaging and advanced technologies like automated object recognition and anomaly detection, ensuring more effective and efficient threat identification. With our autoscan and multi-lane screening, we offer high-speed solutions powered by AI, which significantly optimize throughput and enhance security measures at inspection sites.”

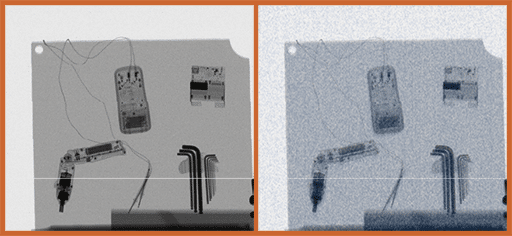

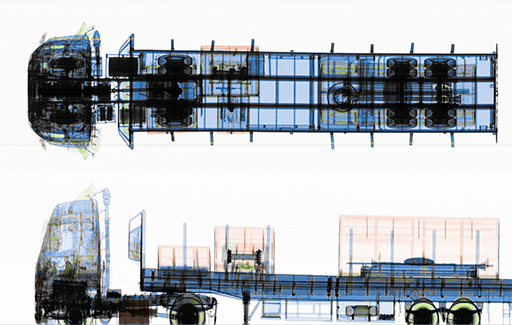

Linev images.

Wide-Ranging Threats

As one might expect, the security issues being faced by ground transportation companies are far-ranging in nature. In particular, “transportation clients are increasingly facing challenges in identifying threats such as contraband, explosives, and weapons within dense cargo or passenger vehicles, all whilst attempting to maintain fast throughput and minimizing operational disruptions,” said Keeler.

These same threats are being faced by customs officials. “Our customers have a tough balancing act; namely, to execute effective security screening measures while keeping the flow of commerce across borders,” Van Gelder said. He cited the detection and apprehension of narcotics, weapons, tobacco, stolen vehicles, high value art, and trafficked humans as top priorities for border control officers.

“Another issue for customs agencies is manifest discrepancies where bad actors attempt to thwart taxes and tariffs by mislabeling manifests,” Van Gelder added. “This means the items or products listed on the manifest do not match what is being transported. When these situations are not detected, it can have a negative impact on a country’s revenue and trade control measures.”

According to Rob Keeler, there are three major factors currently affecting the efficacy of transportation security screening.

The first is an ongoing industry demand for faster, more accurate screening. “Traditional manual or other sensor checks slow down logistics, causing congestion at border checkpoints, ports, and other critical infrastructures,” said Keeler. “This is where our automated scanning capabilities are a favored feature with our users.”

The second factor involves the sophisticated concealment techniques being used against screening systems. “Criminals are using more complex methods to hide threats, including dense packaging and hidden compartments that are harder to detect,” he said. “Multi-energy technology provides high resolution and deep penetration capabilities and achieves multi-energy source fusion using AI.”

The final factor is the need to keep security screening systems at maximum availability through real-time monitoring and predictive maintenance. “Security operators need constant system performance insights to prevent downtime and ensure seamless operation,” explained Keeler. Fortunately, “AI-driven automation and multi-energy screening technologies are helping tackle these problems by improving scanning speed, applying a modular array build, and predictive system management, ultimately improving security and operational efficiency. Our newest build designs allow for end users to seamlessly upgrade their current setups throughout the lifetime of the systems, ensuring scalability and making them future proof.”

The Tools of the Trade

Today, security and customs officials are employing full-vehicle mobile X-ray scanners, fixed X-ray “portal systems”, and multi-lane X-ray screening systems to detect and apprehend contraband of all kinds.

Modern full-vehicle mobile scanners are proving to be effective detection tools. The reason? “These systems provide high-resolution, AI-assisted scanning of trucks, buses, and cargo containers in real time,” Keeler said. “They are capable of detecting anomalies, identifying hidden compartments, and spotting prohibited items through multi-energy imaging and AI-powered material differentiation. The mobile nature of these scanners makes them ideal for use at temporary checkpoints or in rapidly evolving environments.”

“Mobile scanners are designed to excel in dynamic operational environments,” agreed Van Gelder. “They can be deployed in moving or stationary mode and typically have multiple scanning modes and material discrimination to detect a wide array of threats. A key value that these systems bring to security screening operations is their ability to go where needed. In fact, our mobile systems are used heavily at seaports due to their ability to travel to multiple screening locations at the port to scan cargo trailers.”

Because of their relatively small size and maneuverability, mobile scanners are also being used to check vehicles entering large sporting events. “These events can have anywhere from 30,000 to more than 80,000 spectators, players, and venue staff present,” Van Gelder said. “Screening vehicles needing access to these massive arenas is a vital component of the overall security required to help keep everyone safe.”

In contrast, stationary drive-through portal systems offer higher throughput scanning capabilities in locations with a lot of vehicular traffic, such as border crossings. “These systems can comprise a variety of technologies and serve as the first line of defense for customs operators,” said Van Gelder. “Our portal systems leverage X-ray, a combination of X-ray and backscatter, and radiation detection technologies. Threat detection algorithms are typically optimized for the threats most prevalent to the region.”

Finally, AI-enabled multi-lane X-ray screening of vehicles can process even more vehicles on a minute-by-minute basis. “Our Multi Energy Array Portal system, for example, enables parallel screening with enhanced autoscan and threat recognition, significantly boosting throughput at high-traffic locations,” Keeler said. “Together, these technologies automate screening decisions, increase operational efficiency, and provide security teams with real-time analytics for better decision-making.”

Regardless of whether using a mobile or stationary system, training is crucial. “There is a distinction between static and portable/mobile X-ray devices: as the mobile screening is not carried out in specially protected areas, there is a risk of visual or acoustic distractions of the screeners,” said Erich Kramer, director of consulting and training at Security Training International (STI). “A high level of concentration is therefore required when evaluating X-ray images. This must be trained accordingly. Therefore, the quality of X-ray image interpretation trainings is of utmost importance, particularly the instructor-led trainings.”

Trends Driving X-Ray Screening

Several trends are driving the development of new X-ray screening systems. Chief among them is AI-powered autonomous screening. “The industry is moving toward fully automated AI decision-making systems, reducing reliance on human operators, improving efficiency, and minimizing false alarms,” said Keeler.

At the same time, the analytical capabilities of modern AI are so sophisticated that the addition of this technology to X-ray screening systems is transforming them from “dumb” imaging systems (human viewers required all the time) into “intelligent” detection systems (humans alerted to machine-detected anomalies only as required).

As a result, “our customers are shifting away from ‘buying’ AI for the sake of having it and instead are focusing on requirements that drive responsible AI capabilities and mission outcomes,” Van Gelder said. A case in point: “The need for greater transparency, efficiency, and risk mitigation is driving innovations in automated document verification, AI-based risk scoring, and predictive analytics for compliance management,” he said. “Additionally, AI is being integrated with customs and regulatory systems to enhance resilience, reduce manual intervention, and help enable seamless cross-border trade.”

In parallel, new policies governing customs regulatory enforcement, compliance, and digital customs declarations are prompting the development of automated compliance tools to deal with them; again, aided by AI. In fact, “as regulatory requirements become more stringent, AI is becoming essential for supporting real-time adaptation and operational efficiency,” said Van Gelder. “The rapidly evolving threat landscape is also accelerated by technologies like generative AI, agentic AI, and quantum computing.”

For Leidos, this trend is motivating the company to invest in sustained, trusted AI capabilities that are tailored to real-world environments. “At the forefront is preemptive cybersecurity, which is an integral component of our products,” Van Gelder said. “Anything that translates into operational efficiency for our customers impacts how we develop and deliver our solutions. Whether that is reducing bandwidth required in connected solutions, reducing computational and power demands, providing high-performance scanning on smaller platforms, reducing fuel consumption, or delivering AI-assisted analysis to drive better detection rates, an ‘across-the-board’ focus is vital to help our customers do more as their environments grow in complexity.”

In addition to AI integration, LINEV Systems is developing products to address three more trends in ground transportation contraband detection.

The first trend is a move to Multi-Energy Array (MEA) technology. “This next-generation AI-enhanced technology offers improved penetration, better resolution, and superior material differentiation compared to traditional dual-view X-ray systems, making it ideal for cargo and vehicle inspections,” said Keeler.

The second trend is creating detection systems that meet operators’ demand for remote equipment monitoring and predictive maintenance. “Operators now require centralized, real-time tracking of system health, predictive diagnostics, and automated performance monitoring to ensure continuous uptime,” he said.

The final trend is the ability to integrate AI-enabled X-ray screening systems with customs/security data networks. “Compliance with UFF (Unified Freight Framework) and seamless interoperability with customs databases are becoming essential for border security solutions,” said Keeler. “Overall, these trends are pushing the development of smarter, more adaptive, and fully automated security systems that reduce human error and accelerate operations.”

What’s New for Leidos and LINEV Systems

With AI playing such a transformative role in X-ray screening systems, it makes sense that Leidos and LINEV have unveiled several advanced new products in recent months.

Let’s start with Leidos. “We recently launched an enterprise software platform called Mezzo to enable our customers to improve their security screening operations through automation and AI,” Van Gelder said. “Our open architecture platform provides integration of non-intrusive detection devices and other operational data sources into a centralized command center. We also deploy our Trusted-Mission AI to improve threat detection algorithms. For customs and other national security agencies, Mezzo helps identify and distinguish threats with improved accuracy and efficiency to streamline and optimize their screening operations.”

In 2024, Leidos introduced the VACIS MLX, which is the newest mobile screening solution in its VACIS product line. “The VACIS MLX has an industrial chassis and features the shortest wheelbase and the lightest weight in its class, making it easy to maneuver and manage in tight or crowded spaces,” said Van Gelder. “It also has a powerful linear accelerator X-ray source, sensitive detectors, dual-energy material discrimination, and a reduced radiation safety exclusion zone. The new MLX system currently being deployed in Europe provides security inspectors with high-energy X-ray screening to search for weapons, contraband, undeclared cargo, and other items of interest in passenger vehicles and cargo containers with increased speed and accuracy.”

Leidos is currently launching a new portal system internationally that integrates its existing IP6500 dual-energy X-ray system with other advanced screening technologies. This combined system is designed to provide checkpoints at land ports of entry with a nearly 360-degree interior view of cargo containers. “The low radiation dose allows operation in extremely small spaces with no need for shield walls or containment buildings,” said Van Gelder. “As well, when we deploy this advanced capability, we can complete any necessary civil works. This enables us to offer a comprehensive, fast and cost-effective solution for our customers.”

For its part, LINEV Systems has launched several new AI-driven solutions aimed at enhancing vehicle and cargo inspection. One of these is the company’s Multi-Energy X-ray Array Portal (MEAP). “This next-gen scanner integrates MEA technology for superior detection of small contraband, high-risk items, and electronics hidden inside dense cargo, as well as those nasty larger threats,” Keeler said. The second is LINEV’s Automated Screening Solution. “It is an AI-powered, high-speed screening feature that enables multiple units to operate in parallel, eliminating bottlenecks and reducing wait times while maintaining high detection accuracy,” he noted. And the third are AI-Powered Mobile Vehicle Scanners: “These mobile scanners use AI to enhance material differentiation and object recognition, delivering fast and accurate threat detection in remote or high-risk areas,” said Keeler. “Together, these products are designed to maximize security outcomes, improve operational efficiency, and provide real-time insights for security operators.”

Getting the Most Out of Modern Screening Solutions

Given that AI-enabled X-ray screening systems are central elements of their businesses, Leidos and LINEV Systems naturally have lots of suggestions to help customers get the most out of them.

For a change, let’s start with LINEV Systems’ ideas. Rob Keeler has the following four recommendations:

• Leverage AI-driven automated threat detection: “By activating AI-powered risk analysis, clients can reduce false alarms and speed up decision-making processes,” he said.

• Utilize remote monitoring and system health tracking: “LINEV Systems’ solutions offer predictive maintenance and real-time performance insights to prevent downtime and optimize efficiency,” said Keeler.

• Deploy multiple screening units in parallel: “In high-traffic areas, using parallel AI-powered units improves throughput without compromising detection accuracy,” he said.

• Adopt Multi-Energy Array (MEA) technology: “Upgrading to MEA-based scanners enhances penetration capabilities and material differentiation, making it easier to detect complex threats,” concluded Keeler. “By following all four of these best practices, clients can enhance security while maximizing the efficiency of their operations.”

Leidos’ Michael Van Gelder takes a different approach to answering this question. “Better performance for our customers means improved mission outcomes,” he said. “The introduction of our Mezzo suite of products is intended to provide our customers with a new way of exploiting the data generated in their border management operations, leveraging their existing fleet of scanning systems, trade systems, and personnel. Across the board, Mezzo is designed to offer improvements in training standardization, detection capability, personnel engagement, and operational scalability.”

Worth noting: “Mezzo aims to give our customers the additional support they need to maximize their security screening operations — whether they use Leidos scanning systems or not,” said Van Gelder. “The built-in functionality and automation will support personnel to focus their efforts on the adjudication process and any scan results requiring secondary inspection.

Conversely, Leidos and LINEV Systems have run into a few challenges when selling these advanced products to the market and getting clients to understand their total value.

“Technology moves at a rapid pace, meaning we must stay in lock step with our customers whenever new or evolving technologies can impact their mission outcomes,” Van Gelder said. “Alignment often goes beyond the technology into operational or architectural strategy, policy, and governance. In this sense, we are challenged to support alignment between their mission trajectories and our research and development pipeline — we want to invest in solutions that improve outcomes and add value to their missions.”

Meanwhile, LINEV Systems runs into problems associated with educating clients on the benefits of AI automation, demonstrating the superiority of MEA technology, and ensuring seamless integration with clients’ existing security networks. “Many organizations are still reliant on manual X-ray screening, so transitioning to fully automated AI systems requires a shift in security protocols and workforce adaptation,” said Keeler. “While dual-view X-ray systems are familiar, MEA technology offers much better penetration and resolution, so educating clients through live demonstrations and data-driven results is crucial. Finally, clients need our solutions to integrate smoothly with their customs, logistics, and regulatory systems; and they do.”

What’s Coming Next

Today’s smart AI-enabled X-ray screening systems are vastly superior to the dumb viewing systems of the past. But the future is promising to deliver much, much more.

“At LINEV Systems, we’re continuously innovating and developing the next generation of AI-powered security solutions,” Rob Keeler said. “They include fully AI-autonomous screening using AI models that classify and process threats without human intervention; and next-level multi-energy scanning solutions that will eliminate blind spots, improve material differentiation, and enhance imaging clarity for even the most complex cargo. As well, our new systems will feature real-time AI-driven monitoring, predictive diagnostics, and centralized performance tracking, enabling clients to optimize operations across multiple scanning locations. We’re also developing AI-powered mobile vehicle scanners that will provide advanced object recognition, automated threat profiling, and adaptive scanning configurations to make vehicle inspections faster, smarter, and more reliable.”

As for Michael Van Gelder’s view of the future? “As described above, Leidos is launching and enhancing multiple new product offerings, each underpinned with Mission Cyber Resilience and AI-driven solutions,” he replied. “To further enhance our screening products, we also integrate third-party algorithms. Mezzo is the platform that enables this capability in vehicle and cargo screening, providing our customers with greater flexibility to expand their prohibited items list as market dynamics change.”

The bottom line: As delivered by Leidos and LINEV Systems, the X-ray screening systems of today and tomorrow are AI-driven solutions that work in partnership with human officers to quickly and effectively detect and report contraband. As smart as today’s criminals and smugglers may be, these technologies are smarter.